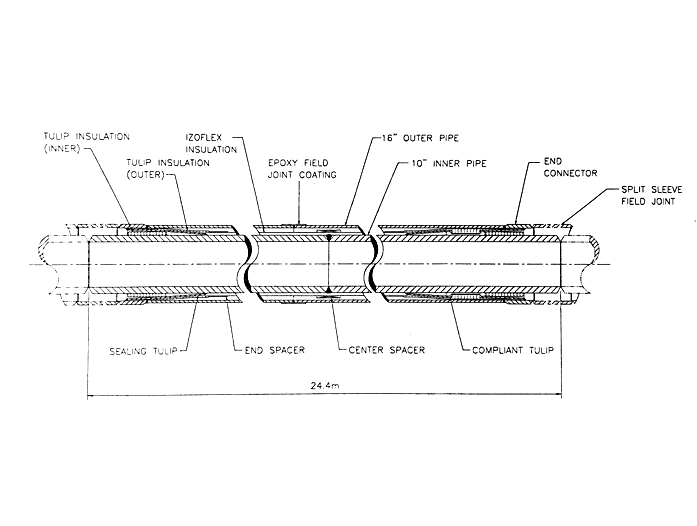

Custom design with tulip inserts to ensure distributed strain coupling to handle thermal expansion and transients.

First Use of Izoflex as pipeline insulation providing a U-value of 1,2 W/m2.K in a compact deign.

Full penetration outer pipe welding coupled with tulip design allowed for required expansion and fatigue behaviour.

Swage J-lay PIP provides strain coupled design ideal for predictable and distributed behaviour of the flowline at high temperatures.

PIP designed for the mechanical constraints and fatigue associated with deep water installation and operation.

Ultra compact design with only 5 mm Izoflex to obtain the required U-value. This means better stability and less materials.

Single-joint PIP provides access to high performance U-value whilst enabling PIP installation with local lay-barge.

Robust implementation for market leading performance fabricated in-country.

Ultra compact design to obtain the required U-value. This means lower top tensions, better stability and less materials.