Ultra High Temperature PiP

Our Ultra High Temperature PiP enables the transfer of very hot working fluids typically super-heated vapour or moltens salts, that also may require heating.

Key advantages

Our Ultra High Temperature pipelines address the challenges of both the thermal and mechanical design associated with these complex systems.

Provides low U-value, with a long passive cooldown

Ensure flow assurance through heating

Provides a low OPEX

Provides low U-value, with a long passive cooldown

Ensure flow assurance through heating

Provides a low OPEX

Market Needs

Applications where high temperature working fluids are required for example solar concentrator or small scale nuclear generation, where efficient transport of energy is critical. At high temperature, pipelines system required attention to both temperature and mechanical design considerations.

- Super-heated steam or air, typically in excess of 500°C, can be found in solar concentrators, nuclear generators and petrochemical processes.

- Molten salts, commonly used in thermal energy storage systems, often operate at temperatures around 600°C, helping to store and transfer heat efficiently.

Why PiP?

ITP Interpipe has the know-how to conceive qualify and implement custom designed solutions with demanding mechanical and thermal constraints. ITP Interpipe operates through formal technologies readiness levels to allow structure solution development.

- Compact and Efficient Design: Izoflex HT® provides low U-values at high temperature, minimizing heat loss for these efficiency critical applications. The low conductivity of Izoflex also provides compact solutions where in-plant space is limited. Izoflex’s non-ageing properties mean no maintenance, which helps significantly reduce long-term operational costs (OPEX).

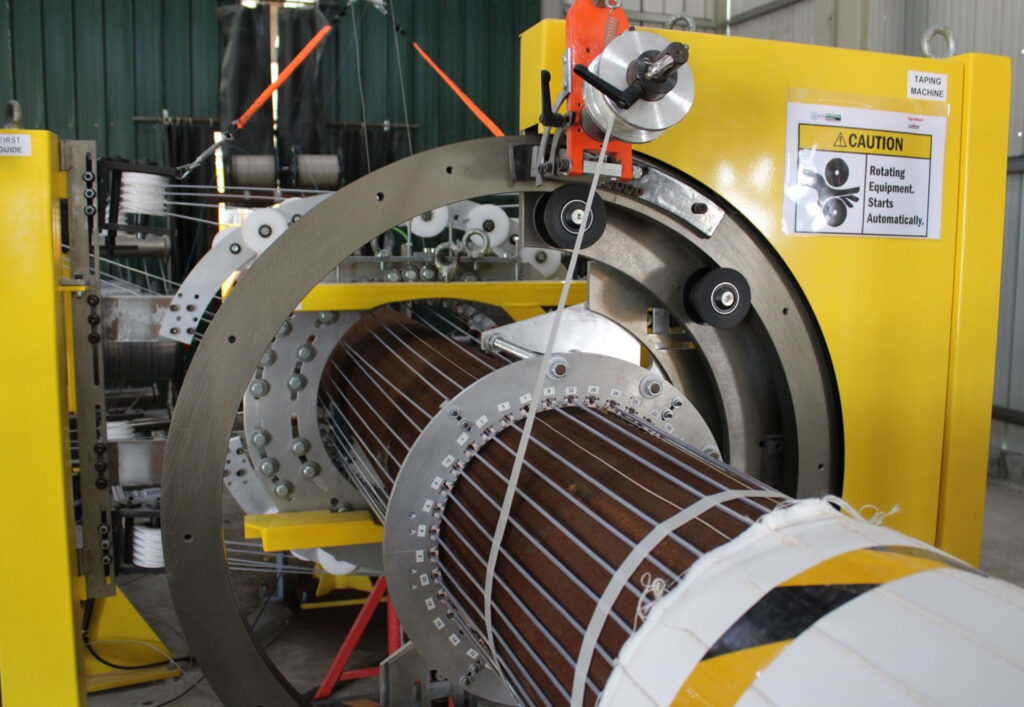

- Heat Tracing with AsphaltAx®: AsphaltAx® is designed specifically for high-temperature fluids, allowing for temperature maintenance during shutdowns. The heat-traced wires can withstand temperatures up to 600°C, providing reliable performance even in the harshest conditions.

Your Benefits

We are able to develop a fit-for-purpose solution for your project constraints, incorporating both mechanical and thermal requirements

- Energy Efficiency and Low OPEX: Our Ultra High Temperature PiP systems are designed with a low U-value, ensuring that energy is used efficiently, and heat loss is minimized. This translates to enhance production, reduces energy consumption, and more sustainable operations.

- Zero Maintenance: Thanks to the advanced, non-ageing Izoflex insulation, our Ultra High Temperature PiP systems require little to no maintenance, drastically reducing long-term operational expenditures and increasing system longevity.

- Versatility for High-Temperature Fluids: Our pipeline design is suited for a wide range of high-temperature applications, including but not limited to steam and molten salts, and can incorporate various pipe metallurgies. This versatility makes our solution highly adaptable to diverse industries, such as energy production, chemical processing, and refining.

- Optimized Flow Assurance: Heat tracing can be incorporated into the PiP system to avoid working fluid solidification during shutdown and enable immediate restart, thus enhancing production.