Heat Traced Flowlines

Our Electrical Heat Traced Flowlines (EHTF) provide active heating, preventing wax and hydrate formation, ensuring flow assurance, and enhancing production with single-line tiebacks and provides viscosity control for bitumen and Sulphur.

Key advantages

Our Electrical Heat-Traced Flowlines are perfect for hydrate and wax mitigation. They enable pressurized shut-in and independent flowline control, simplifying operations, improving flexibility, and minimizing production downtime for reliable, continuous flow assurance in challenging conditions.

In downstream industries, the heat tracing is used for operations and shutdown scenarios for viscous fluids like bitumen and liquid sulphur.

Mitigates chemical use

Allows for independent pipeline operation

Enables single-line tiebacks

Eliminates hydrate and wax risk

Reduces risks of production upsets / unplanned shutdowns

Enables long distance bitumen transfer & batch loading

Mitigates chemical use

Allows for independent pipeline operation

Enables single-line tiebacks

Eliminates hydrate and wax risk

Reduces risks of production upsets / unplanned shutdowns

Enables long distance bitumen transfer & batch loading

Market Needs

In offshore oil and gas production, managing hydrate formation and wax buildup is essential for operations. Hydrate and wax formation cause pipelines downtime and complicate operations. However, traditional flow assurance methods, like using chemicals, have drawbacks, including the need for additives, costly energy use, and added operational complexity. In contrast, our heat-traced flowline directly addresses these challenges. By providing active, resistive heating through electrical elements within the PiP annulus. Thanks to the combination of extremely low U-values and efficient resistive heating allows for flow assurance using an order of magnitude less energy than alternative solutions.

- Bitumen: Bitumen is typically transported around 180°C, bellow which temperature pumping is complicated. The electrical heat-traced pipeline maintains bitumen at high temperature during pipeline shutdowns, allowing immediate restart when required.

- Sulphur: Liquid Sulphur needs to be maintained in a very narrow temperature window around 130° in order to be transport by pipeline. The electrical heat-traced flowline can provide this precises temperature control through efficient use of Izoflex and heat-tracing.

Why PiP?

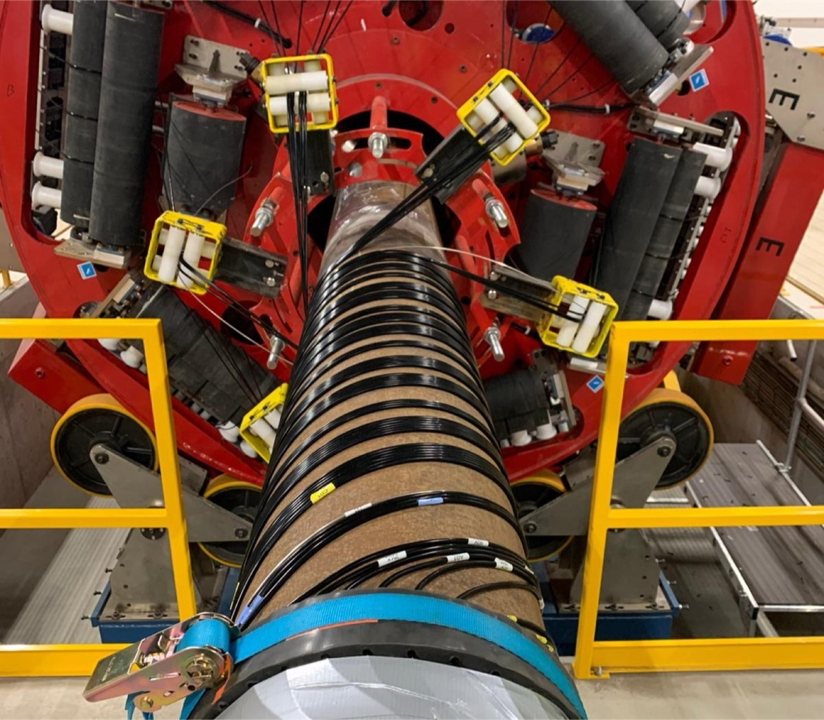

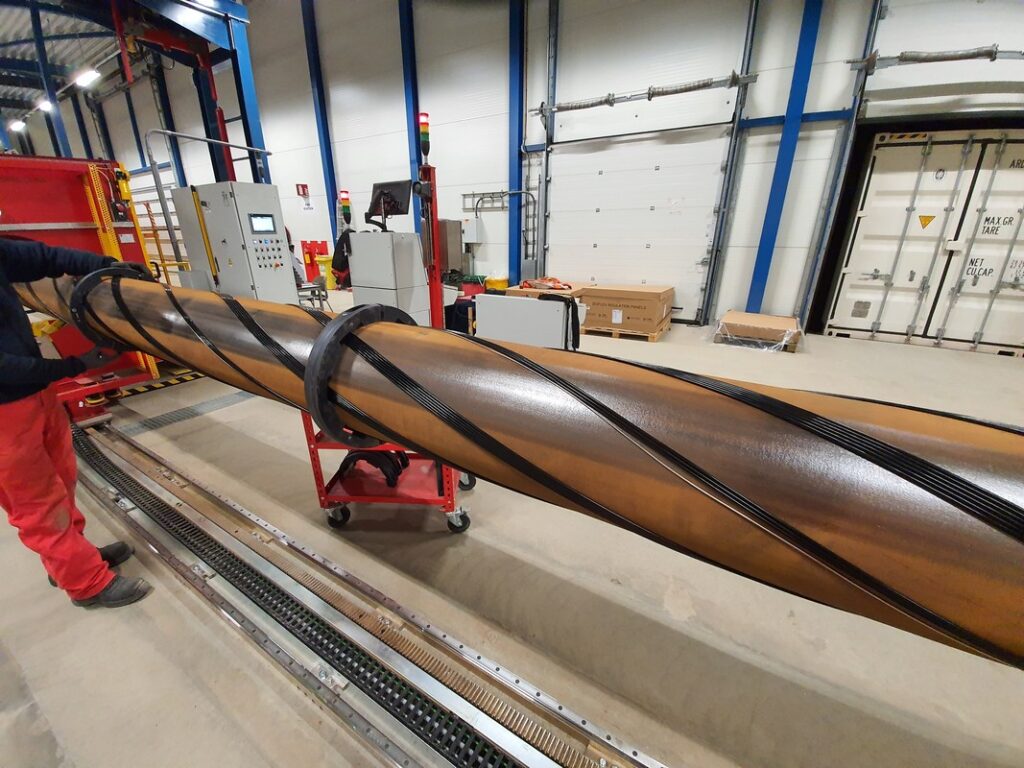

The EHTF integrates heating wires beneath the Izoflex Insulation within the PiP anulus. As a result, all energy dissipated by the heating wires is available to fluids being transported. Moreover, the highly efficient Izoflex insulation provides low U-values meaning a small amount of energy is required for infinite no-touch times.

-

- EHTF®: The EHTF resistive heating is enable by the excellent thermal performance provide by the PiP. Pipeline heating is independent of pipe metallurgy, since no current is passed in the pipeline itself.

- Izoflex®: Highly efficient insulation that delivers the lowest conductivity in the pipeline industry, ensuring effective heat retention and minimizing energy consumption.

-

- FlowsurAx®: A specialized wire architecture developed specifically for the EHTF system, tailored to meet the unique demands of the environment. Our expertise in electrical system design enables us to offer customized electrical testing, ensuring reliability for the project lifetime.

- Single-Line Tiebacks: EHTF supports unique, simple single-line tieback configurations that do not require additional flow assurance systems, providing simplified operations and enhance production.

In partnership with Subsea 7 our subsea electrically heat traced flowlines are deployed using reeling techniques and Subsea 7’s state-of-the-art vessels. As the result, this innovative solution enables single-line tieback architectures, eliminating the need for traditional flow assurance methods, such as chemicals, thus streamlining operations.

Your Benefits

Our EHTF technology offers significant advantages that directly address your needs, ensuring enhanced performance and efficiency across key areas:

- Energy Efficiency: The heat trace system requires significantly less power; 10 to 15 times lower than conventional direct electrical heating (DEH) systems.

- Low Conductivity: With the Izoflex insulation, the flowline system retains heat effectively, reducing the power needed for operation while also allowing for larger flow diameters within the same outer pipe diameter.

- Predictable Corrosion Behavior: Since there is no current passing through the pipeline, the risk of corrosion is minimized, and traditional corrosion protection techniques can be reliably applied.

- Operational Flexibility: The combination of low conductivity insulation and resistive heating allows for infinite “no-touch” times, enhancing overall operational flexibility and reducing the frequency of interventions.